VFDs in Pumping Systems: Enhancing Efficiency and Control

VFDs in Pumping Systems: Enhancing Efficiency and Control

Variable Frequency Drives (VFDs) are powerful tools for optimizing pump operations, offering significant energy savings and improved process control. This article explores their benefits, challenges, and key considerations for implementation.

Introduction to VFDs in Pumping Systems

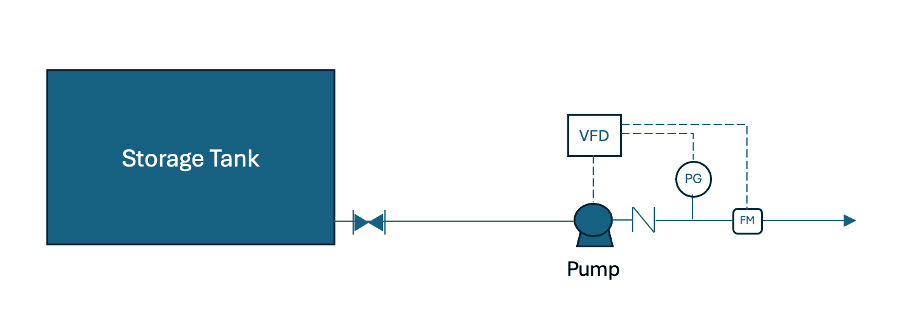

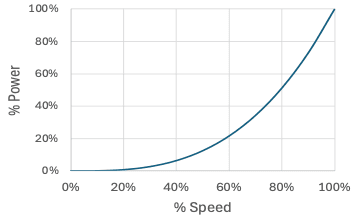

Variable Frequency Drives (VFDs) are used on motors to control pump speed, allowing for precise adjustment of flow rate and significant reduction in power consumption. Operating a pump at 80% of its rated speed can halve power consumption, directly impacting energy costs (OPEX) while improving equipment longevity and system reliability through reduced component wear.

Key Benefits and Considerations

Benefits of VFDs:

- Highest potential reduction in energy consumption

- Improved efficiency gains

- Enhanced process control flexibility

Challenges and Considerations:

- Higher initial costs (increased project CAPEX)

- Additional design and space requirements

- Potential for increased system complexity

- Generation of harmonics, potentially interfering with control systems

- May require EMI/RF filters and more expensive VFD-rated cables

VFD considerations must be handled on a case-by-case basis when determining financial justification for extra investment. A comprehensive financial analysis (NPV, ROI, Payback) should be conducted for options with and without a VFD.

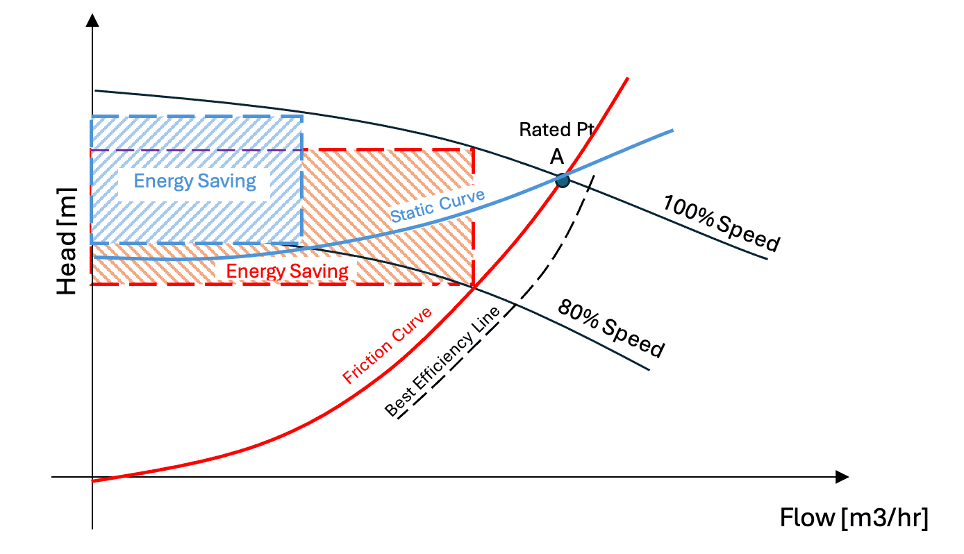

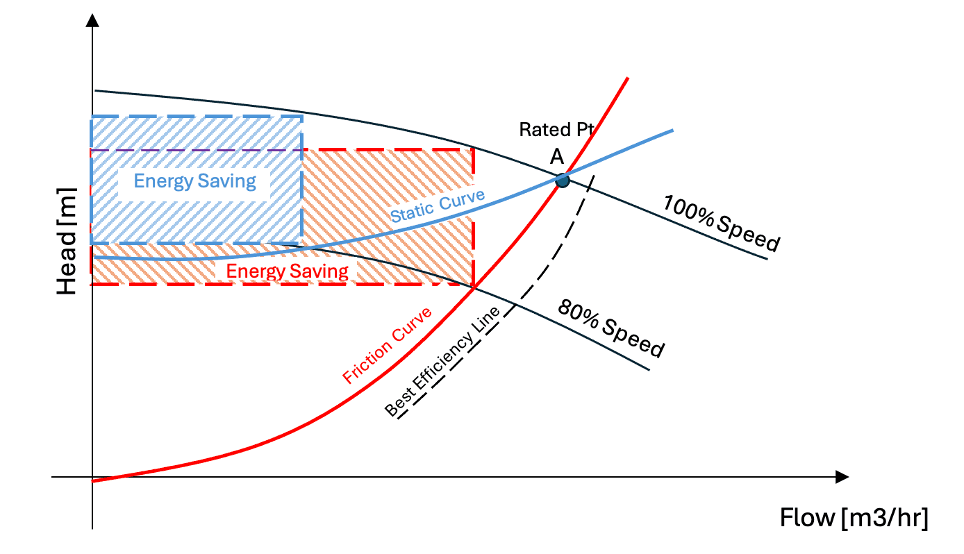

Energy Savings Potential

The energy saving potential of VFDs is largely dictated by the pump's system curve:

- Friction dominated curves offer the highest potential for energy savings

- Static head dominated systems have flatter curves, constraining energy saving gains when reducing speed

- Most systems are a combination of both friction and static head

Why This Matters

Understanding the implications of VFDs in pumping systems is crucial for:

- Optimizing energy efficiency in industrial processes

- Reducing operational costs and environmental impact

- Enhancing system control and flexibility

- Aligning with Net Zero strategies and sustainability goals

Did You Know?

- VFDs can reduce energy consumption by up to 50% in some pumping applications.

- The global VFD market is expected to reach $27.57 billion by 2026, driven by increasing energy efficiency regulations.

- VFDs can extend the life of pump systems by reducing mechanical stress and wear.

Further Reading

For more in-depth information on VFDs and their applications in pumping systems, consider exploring these resources:

- U.S. Department of Energy - Adjustable Speed Drive Part-Load Efficiency

- Hydraulic Institute - Variable Frequency Drives

Summary

VFDs provide a powerful solution for reducing energy consumption in pumping systems and are commonly prescribed as part of a Net Zero Strategy. They offer significant advantages in terms of energy efficiency, equipment longevity, and process control. However, they also come with challenges such as higher initial costs and increased system complexity.

Careful consideration and proper management are essential to maximize the benefits of VFDs in pump applications. While it might be difficult to financially justify their use in some applications, the regulatory landscape and corporate sustainability strategies may provide compelling arguments for adoption.

While every effort has been made to provide a comprehensive overview of best practices and challenges in using VFDs, Fluensys does not claim that these will successfully apply to every business and reserves the right to adjust their technical opinion to reflect latest practices and specifics of application.

Contact

For more information and support, please contact:

Dr Jean-Noel Bajeet FIMechE CEng

Lead Consultant

Jean-noel.bajeet@fluensys.co.uk

Download Full Article

Get a PDF version of this article for offline reading and sharing.

Related Articles in [ automation ]

No related articles found in this category.

View All Articles in automationSubscribe to Our Blog

Stay updated with our latest articles and insights.