PUMPING SYSTEMS CONSULTANCY

Access to Expertise and Knowledge in Fluids Pumping for SMEs

OUR SERVICES

New Products & Capital Projects

We support product development and innovation projects to help drive performance, reduce development cost and shorten time to market.

Refurbishments & Upgrades

We support ageing asset refurbishment and plant upgrade projects to help reinstate asset integrity and future-proof pumping systems.

Operations & Systems

We troubleshoot machinery and process systems to eliminate recurring mechanical seal failures and instabilities and help reduce operating cost and downtime.

We provide comprehensive services to end users, startups and pump manufacturers.

DESIGN & AUDIT

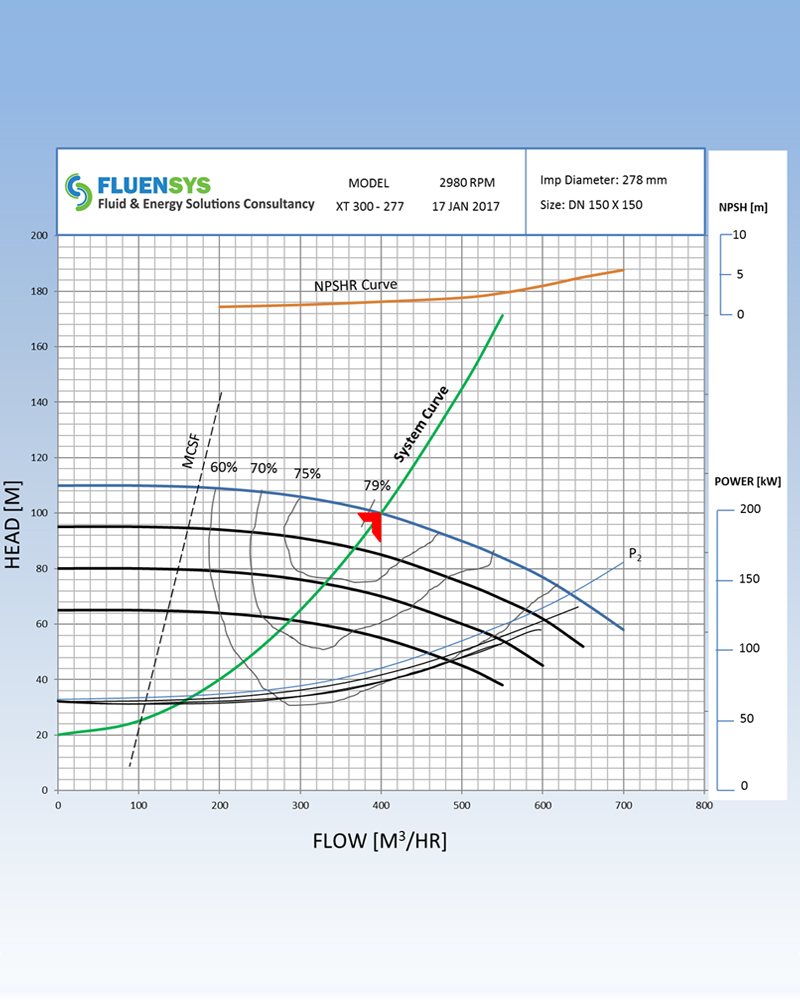

- Pump Selection and System Design

- Pump Design – Impeller & Volute Sizing, Shaft Design, Mechanical Seal and Bearing Selection

- Layout Drawings and Installation Details

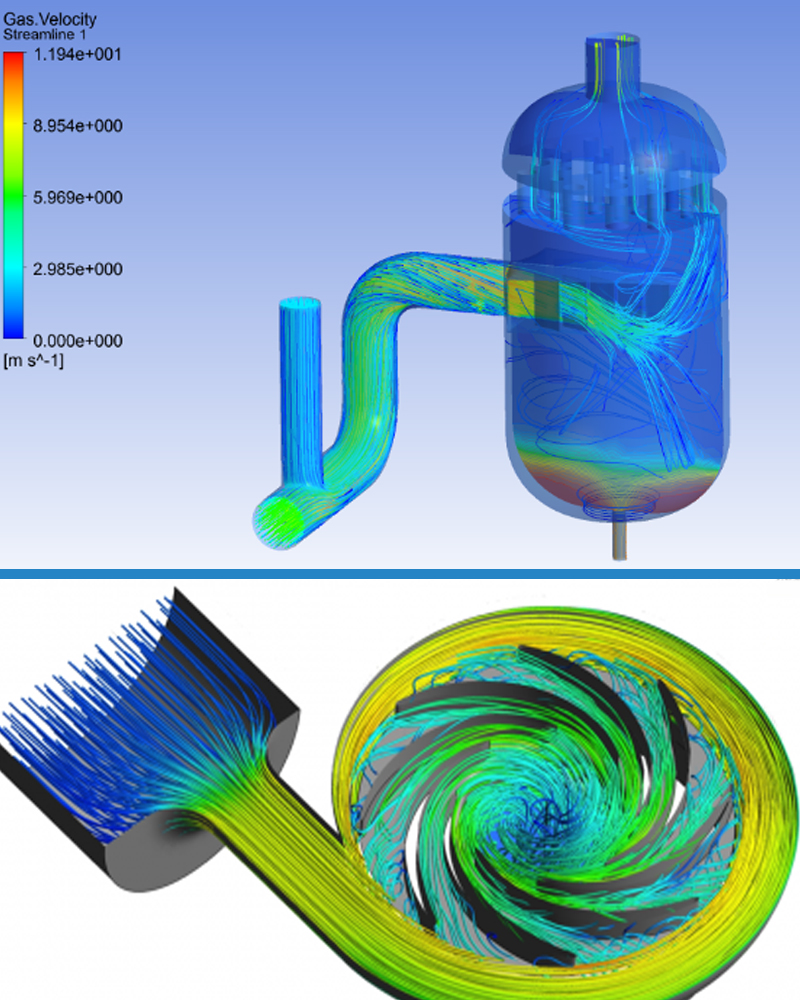

- Model Testing and CFD Analysis

- Pump Re-Rating (Change of duty)

- Dynamic Simulation Analysis (Start-Up/Shutdown/Process Upset)

- Piping and System Design, including Valves and Fittings

- Materials Selection for Pumping Application

- Witness Testing (FAT/SAT) – ISO 9906/HI/API 610/PTC 22

- Non-Destructive Testing (NDT) – Pipework Pressure Rating (ASME B31)

OPERATIONS

- Plant Operational Review

- Off-design Operation Analysis

- Dynamic Simulation Analysis (System trip)

- Vibration and Noise Troubleshooting

- Seal Failure Troubleshooting

PROJECTS

- Concept Studies

- Feasibility Studies

- Due Diligence

- Risk Analysis & Mitigation

- New Product Development

- Research & Innovation

- Technical Advisory

TRAINING

- Pump Technology

- Pumping System Design & Operation

- Mechanical Seal Systems

- Common Pump Failures

OUR EXPERTISE

Rotating Equipment

Centrifugal Pumps

- Single Stage Overhang

- Multistage Horizontally Split

- Multistage Barrel Type

- Submersible and Puddle

Special Applications

- Mag Drive

- Sealless

- Multiphase

- SCO2

- Wear Resistant

Positive Displacement

- Screw

- Piston & Swash Plate

- Regenerative

Drivers & Turbines

- Air & Hydraulic Turbines

- Gas Turbines

- Electric Motors

- Turbo Expanders

- Diesel Engines

Applications

- Water & Wastewater

- Oil & Gas Production

- Lubrication Systems

- Cooling Systems

- Slurry & Sand

- Chemical Process

- Power Generation

- Renewables

- CHP

- Boiler Feed Water

- Seawater Pumping

- Multiphase Pumping

- Carbon Capture & Storage

Techniques

- Fluid System Design

- Mechanical Design

- Pump & Hydraulic Design

- Pump Off-Design Analysis

- Experimental Analysis

- Computational Fluids Dynamics

- Thermodynamic Calculations

- Aerodynamic Design

- Rotodynamics Stability Analysis

- Steady State Process Simulation

- Dynamic Simulation

- Economic Calculations: NPV, ROI, CAPEX, OPEX

Our Work

We have experience in Water & Wastewater, Oil & Gas, LNG, Power Generation, Consumer Products and Renewables.

Contact us today for an initial consultation.

Pump Selection

Modelling & CFD Analysis

Troubleshooting

We aim to make a difference by adding value to your business.

Our Mission

We strongly believe in our social responsibility to help SMEs promote sustainable and earth friendly engineering solutions that benefit not only their customers, but also the community and the planet.

We support As Green As Possible (AGAP) solutions.

Our Values

Our core values are Honesty, Integrity, and Responsibility.

We strive to put our skills, experience, expertise and drive at the service of our clients with a commitment to providing optimal solutions that are both environmentally friendly and sustainable.

Our Team

Our consultants draw on their combined 50+ years of Pump & Fluids expertise to develop the best practical, tailor-made solutions for Small and Midsize Businesses.

Dr. Jean-Noel Bajeet

Lead Consultant

Turbomachines & Power systems, Renewables

Jean-Noel holds a PhD in Fluid Dynamics and Turbomachinery and has over 15 years of experience in the pump industry. A specialist in submersible pump design, testing and selection, he has acquired extensive expertise in Water and Wastewater applications, solids handling and abrasive media applications such as sand pumping. He also has experience in Oil & Gas pumping systems (Main Oil Line) and debottlenecking, having supported BP on numerous operational troubleshooting projects. Previously a Hydraulics Designer for ABS (Sulzer) Pumps, Jean-Noel was also a member of the JOULE II European project on Wave Energy Research.

David Cullen

Associate Consultant

Turbomachines & Power Systems, Cryogenics

David has over 40 years of experience working with pumps and pumping systems. A cryogenic (LNG) pump design and selection specialist, he acts as Associate Consultant with Fluensys. Over the years, he has provided consulting services to major companies such as BP and TGE Marine in various sectors including Water, Oil & Gas, LNG and Marine. David avails of a wide experience and knowledge on cryogenic pump applications acquired through numerous LNG projects carried out across the globe. He was previously VP Europe for EBARA Pumps and UK Manager for Worthington Pumps.

Sabbir Mahmood

Lead Process Engineer

Systems Control, Energy Conversion & Fuels

Sabbir holds a Master’s Degree in Chemical Engineering from Imperial College and has over 8 years experience in the oil and gas industry. He is specialized in control systems analysis and dynamic simulations. He has worked extensively on the process design audit and troubleshooting/debottlenecking of compression, pumping and LNG systems. He is experienced in process modelling of systems start-up/shutdown/ESD with over 30 projects in his portfolio. His current research work is in supercritical CO2 and alternative fuels.

Let US HELP YOU turn your Vision into Reality

OUR CLIENTS

TESTIMONIALS

Thanks a million for your visits over the last two weeks. Our Engineers got all they wanted on the pump design and more from discussions. You have given us new energy to tackle this important area.

Technical Director, Sulzer (Ireland) on training course carried out on Centrifugal pumps

(2017)

Many thanks for preparing and delivering the training course for our operational team.

Senior RE Engineer, Repsol Sinopec (UK) on training course carried out on Pumping Modules for Claymore Asset

(2014)

Thanks for the intellectual rigour in producing a highly effective support for us.

VP, Head of Innovation & Marketing, Aqualisa (UK) on pump design consultancy support

(2016)

Get In Touch

Our Head Office

35 Westcliffe House,

Central London, N1 3HS

United Kingdom